Electroplating Melbourne Experts: Shine That Lasts Forever

Electroplating Melbourne Solutions: Add Brilliance to Every Surface

Basic Information

In today’s manufacturing and design industries, appearance and durability go hand in hand. Whether it’s enhancing the look of metal parts or protecting them from corrosion, electroplating stands out as one of the most effective surface finishing processes. Across Australia, and particularly in Melbourne, the demand for high-quality plating services continues to rise as industries seek solutions that offer both functionality and a polished finish. This article explores the expertise, process, and benefits provided by Electroplating Melbourne professionals who are shaping the future of metal finishing with precision and innovation.

Understanding the Process of Electroplating

At its core, electroplating is a chemical and electrical process used to coat a metal surface with a thin layer of another metal. This is achieved by passing an electric current through a solution containing metal ions. The object to be plated acts as the cathode, attracting the positively charged ions that form the outer layer.

The process is not just about improving aesthetics; it also enhances resistance to corrosion, improves electrical conductivity, and increases wear strength. Melbourne’s electroplating experts combine traditional craftsmanship with advanced techniques to ensure that every product achieves the desired finish — from decorative applications to complex industrial requirements.

Why Choose Professional Electroplating in Melbourne

Opting for professional services in Electroplating Melbourne ensures that every component undergoes a meticulously controlled process. Skilled technicians use specialized equipment and carefully monitored chemical baths to deliver consistent, high-quality results.

Some reasons why Melbourne-based electroplating services stand out include:

-

Precision and Consistency: Experts maintain tight control over thickness, adhesion, and surface quality, which is essential for components used in manufacturing, automotive, and aerospace industries.

-

Versatile Finishing Options: From chrome, nickel, and zinc to gold and silver plating, clients can select finishes that meet both functional and aesthetic goals.

-

Eco-Conscious Practices: Many facilities have adopted environmentally responsible methods, using advanced waste treatment systems and reducing chemical consumption.

-

Local Expertise and Support: Melbourne’s electroplating professionals are known for their technical knowledge and commitment to customer satisfaction, ensuring that projects meet exact specifications.

The Role of Industrial Electroplating in Modern Manufacturing

Industrial Electroplating plays a crucial role in extending the life and performance of components used in heavy industries. Unlike decorative plating, which focuses on appearance, industrial plating is designed to improve durability, strength, and conductivity.

Some of the key applications include:

-

Automotive Components: Electroplated coatings protect engine parts, fasteners, and trims from rust and friction, ensuring long-term reliability.

-

Electrical and Electronics: Conductive coatings such as copper or silver enhance electrical performance while preventing oxidation.

-

Aerospace and Defense: Critical parts in aircraft and defense equipment require high-performance plating to withstand extreme conditions.

-

Tooling and Machinery: Industrial electroplating increases wear resistance in tools and mechanical parts, reducing maintenance and replacement costs.

Melbourne’s industrial plating experts combine technical precision with industry standards, making the city a hub for innovation in metal finishing.

Techniques and Materials Used in Electroplating

Electroplating involves a range of metals and techniques tailored to the purpose of the final product. Some of the most commonly used materials include:

-

Nickel Plating: Offers corrosion resistance and a smooth, reflective surface, ideal for automotive and decorative uses.

-

Chrome Plating: Provides a high-gloss finish and superior hardness, commonly seen in vehicle parts and appliances.

-

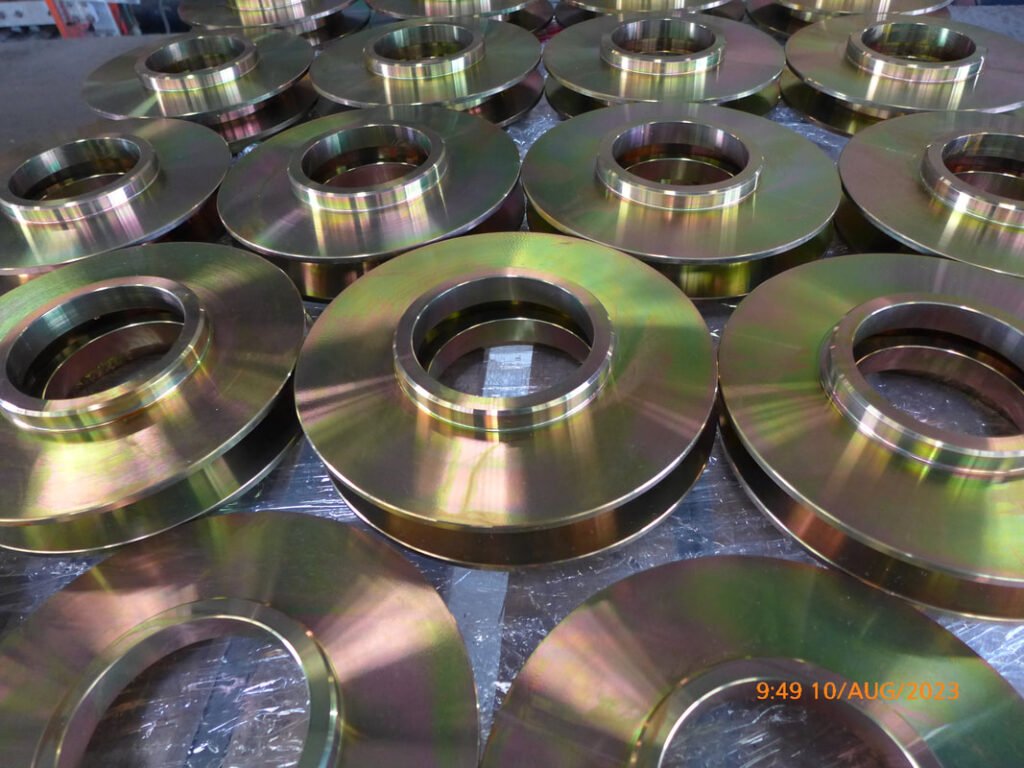

Zinc Plating: Prevents oxidation on steel components, widely used in industrial and construction applications.

-

Gold and Silver Plating: Enhances conductivity and visual appeal, making it suitable for jewelry and electronics.

Melbourne’s facilities are equipped with modern plating lines that support both small-scale custom work and large industrial batches. Each project undergoes strict quality checks to maintain uniformity and performance.

Sustainability in Electroplating

As global industries shift toward more sustainable practices, Electroplating Melbourne services are evolving to align with environmental standards. The process, traditionally associated with heavy metal usage, has been redefined through eco-friendly technologies.

Modern facilities now employ closed-loop water systems, minimize chemical waste, and follow stringent environmental compliance guidelines. Additionally, energy-efficient plating systems reduce overall carbon emissions, making the process safer for both workers and the environment. This focus on sustainability not only meets government regulations but also enhances the reputation of Melbourne’s electroplating sector on an international scale.

Choosing the Right Electroplating Partner

Selecting a reliable electroplating service is a critical decision for manufacturers, designers, and businesses. When evaluating potential providers, consider factors such as:

-

Experience and Specialization: Look for companies that have a strong track record in Industrial Electroplating and a portfolio covering a range of finishes.

-

Quality Assurance: Check for certifications, testing procedures, and adherence to international standards.

-

Technology and Equipment: Modern plating facilities should use automated systems and advanced chemical controls for precision.

-

Customer Service: Communication, turnaround time, and customization options play an important role in successful outcomes.

Partnering with Melbourne’s established electroplating experts ensures that projects are completed efficiently, cost-effectively, and with uncompromised quality.

The Future of Electroplating in Melbourne

As industries embrace innovation, the electroplating sector in Melbourne continues to evolve. The integration of automation, artificial intelligence, and real-time monitoring systems has transformed how surface finishing is executed. These advancements allow for improved accuracy, reduced environmental impact, and greater cost efficiency.

Moreover, the growing demand for electric vehicles, renewable energy components, and precision engineering parts is expected to further boost the need for expert electroplating services. Melbourne’s position as a manufacturing and innovation hub ensures that it remains at the forefront of these developments.

Conclusion

The art and science of electroplating have come a long way from their early industrial beginnings. Today, Electroplating Melbourne experts combine technical mastery, modern technology, and environmental responsibility to deliver finishes that are both durable and visually appealing. From decorative chrome plating to high-performance Industrial Electroplating, Melbourne’s specialists continue to set benchmarks in quality and sustainability. Their work ensures that every component not only shines with brilliance but also stands the test of time — truly, a shine that lasts forever.